Introduction

Working with FlowOpt means that you have an application that has been specially developed for production companies with a high variety of products with short runs. You usually produce to customer order, but you can also produce from stock. The focus is on optimizing the Flow and not on the utilization of resources. hence the name FlowOpt. With resource optimization or long production runs, waiting times and work in progress are quickly created and you make the customer wait longer than necessary. FlowOpt is fully equipped to minimize waiting times and to eliminate or greatly reduce work in progress. FlowOpt supports Quick Response Manufacturing (QRM) but also other lean oriented methods.

Get to know Flow optimization and the processes involved

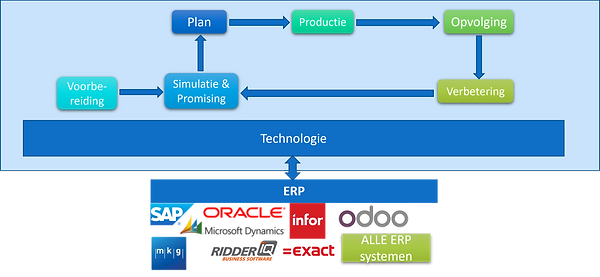

Before you start with e-learning, we first introduce you to Flow optimization and the processes supported by FlowOpt. It will also be clearly indicated how FlowOpt fits within an existing ERP environment.

Flow Optimization vs Resource Optimization

With resource optimization, the machine/employee is fully planned as optimally as possible. This creates waiting times and work in process (WIP). Experience has shown that administrative processes in particular often have a long waiting time. We call the waiting time 'White Space' and the actual production time Touch time or Gray space.

In the example below you can see the total lead time, which largely consists of White Space. The actual production time (touch time) is indicated below for each activity.

Total production time 13 hours.

Since the production time cannot normally be reduced, Flow optimization focuses on reducing/eliminating the waiting time (White space) and Work in Process. This makes it easy to halve the lead time and more. The QRM principle is based entirely on this and in practice has resulted in reductions in lead times of up to 80-90%. Implementing QRM is a process that takes time and cannot be realized overnight. It often also requires organizational change.

Processes

The FlowOpt software supports various business processes, which are role-oriented. The most important processes are the planning process and the production execution process. Each process consists of various sub-processes such as the sales order simulation process, the planning and replanning process and the execution or shop-floor process. These and many other processes are covered in detail in this course.

The processes can be integrated with the ERP processes or run completely stand-alone. In the drawing below you will find an example of the integration of FlowOpt processes in the ERP processes.

Integration into the ERP process

FlowOpt integrates with the following processes:

Sales orders : take over, simulate, schedule and execute/complete.

Purchase orders : for tracking subcontracting

Production orders: take over, simulate, plan and execute/report ready

Inventory management is not yet integrated.

This will be possible at a later date.